산업용 초음파 기기 전문 기술기업 멕스기연

When You Lead, We Support

When You Lead, We Support

When You Lead, We Support

Our Solutions

Ultrasonic Plastic Welding System

Automatic tuning and precise amplitude control ensure consistent welding quality under any operating conditions while minimizing defect rates. High durability and low failure rates enable stable, long-term production operation.

More View

Ultrasonic Metal Welding System

Ultrasonic vibration removes surface oxide layers and promotes direct diffusion and bonding between metal atoms. It delivers low-resistance, high-durability metal joints, making it ideal for electronics, batteries, and automotive electronic components.

More View

Ultrasonic Soldering System

Flux-free oxide removal enables clean, reliable, and environmentally friendly soldering. Materials that are difficult to solder using conventional methods—such as glass, ceramics, and aluminum—can be bonded stably.

More View

Ultrasonic Food Cutting System

Ultrasonic micro-vibration transmitted to the blade reduces friction and prevents adhesion of sticky materials. It provides smooth and precise cutting without deformation for cakes, ice cream, sandwiches, and similar products.

More View

Ultrasonic Industrial Cutting System

High-frequency vibration reduces friction and heat generation, enabling cutting without material deformation. Easily integrated into automated lines, it allows precise cutting of difficult industrial materials such as nonwovens, films, and synthetic resins with minimal damage.

More View

Ultrasonic Screening System

Ultrasonic vibration forms a fine vibration layer on the screen surface, preventing powder adhesion and screen clogging. Even ultra-fine powders are classified accurately without agglomeration, significantly improving productivity and extending screen life.

More View

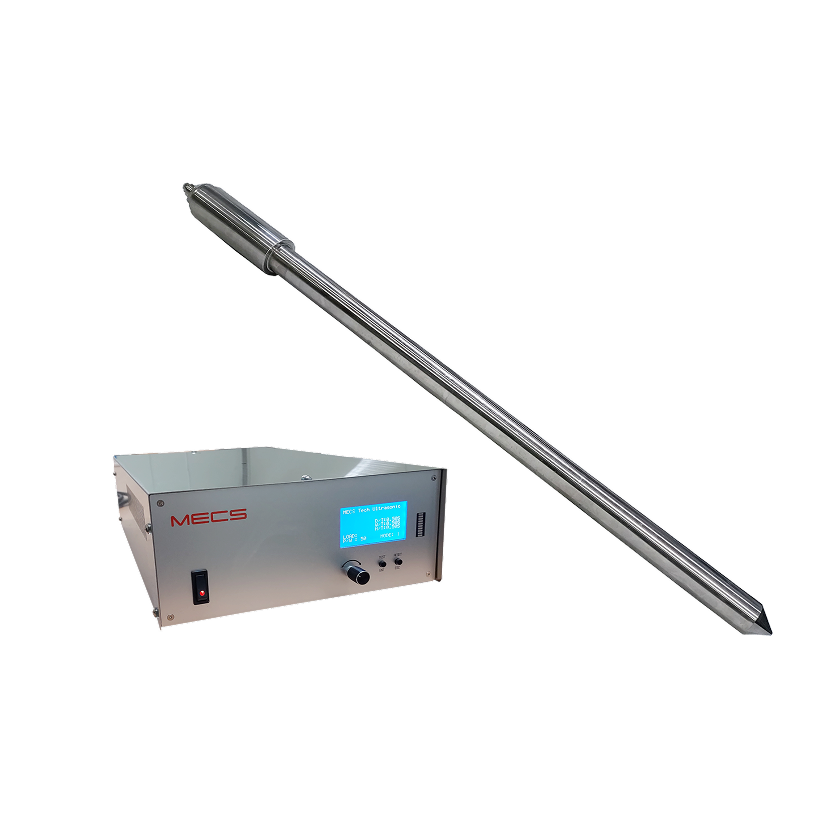

Ultrasonic Rod Cleaner

A special titanium vibration unit ensures stable cleaning performance even during long-term continuous operation. Applicable to dispersion, mixing, fragmentation, and reaction acceleration processes, and capable of stable operation in high-temperature, high-pressure, and chemical environments.

More View

Why MECS?

In-House Technology for Core Ultrasonic Components

MECSTECH possesses proprietary technology for core ultrasonic components, including amplifiers, horns, and transducers. Based on this technology, we design, manufacture, and supply ultrasonic core components in-house.

Industrial Ultrasonic Total Solution Service

From the design stage through manufacturing, installation, and after-sales service, MECSTECH provides a TOTAL SOLUTION for industrial ultrasonic products, delivering comprehensive one-stop technical support.

Free Pre-Purchase Testing Support

All MECSTECH products are eligible for free testing prior to purchase. Customers can verify product performance and quality either through on-site visits or by sending samples in advance.

Industrial Ultrasonic Total Solution Service

From the design stage through manufacturing, installation, and after-sales service, MECSTECH provides a TOTAL SOLUTION for industrial ultrasonic products, delivering comprehensive one-stop technical support.

Dedicated R&D Department

MECSTECH operates a dedicated Research & Development department focused on ultrasonic products, conducting continuous R&D to enhance performance and improve long-term durability.

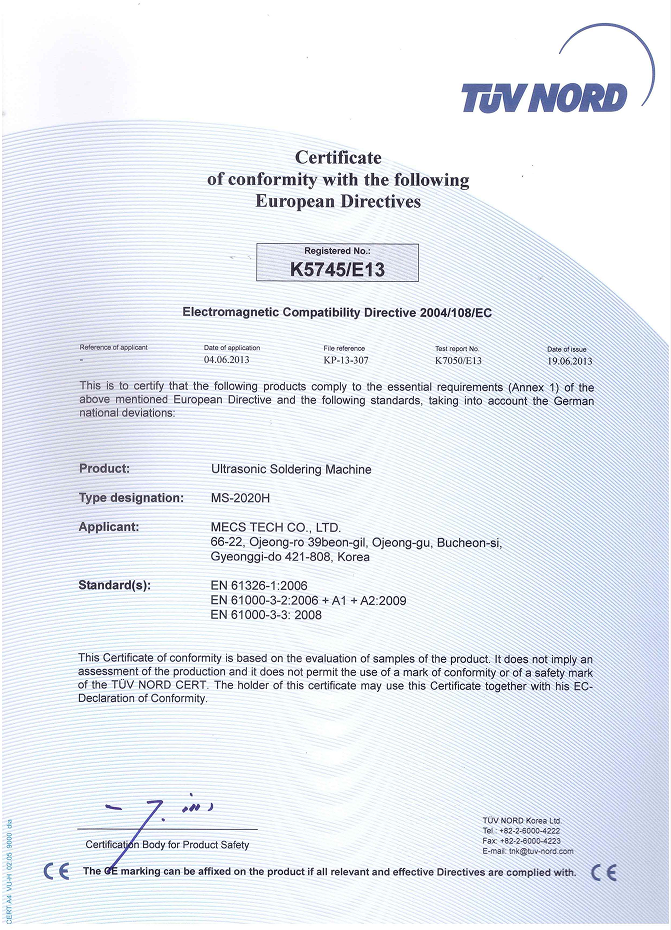

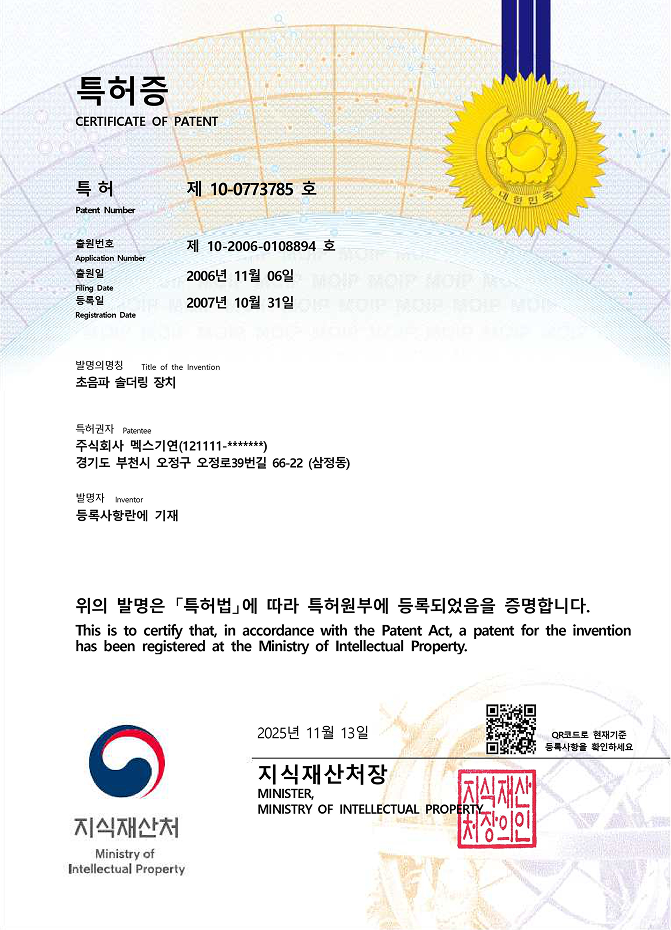

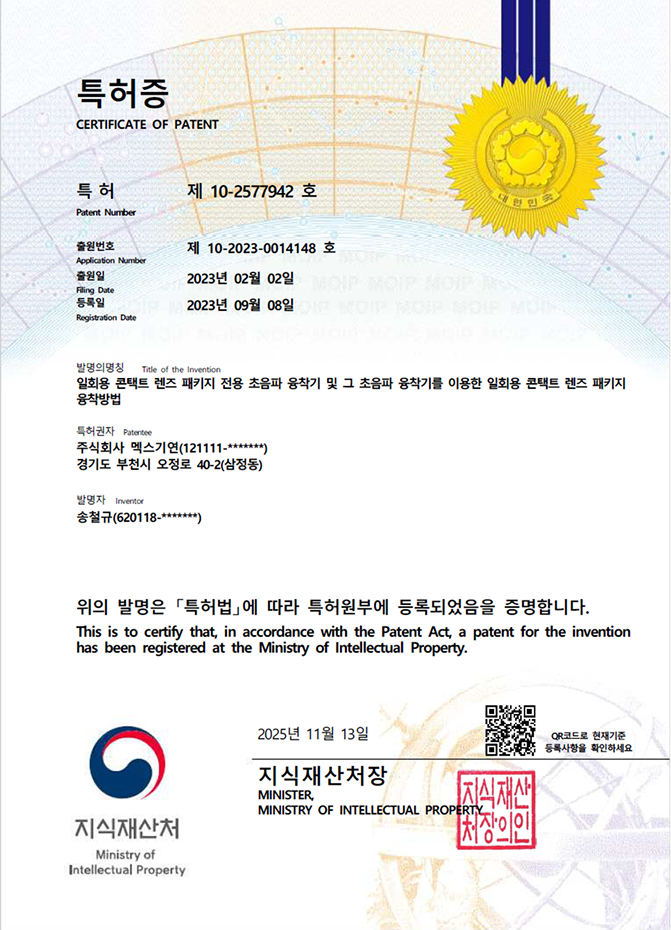

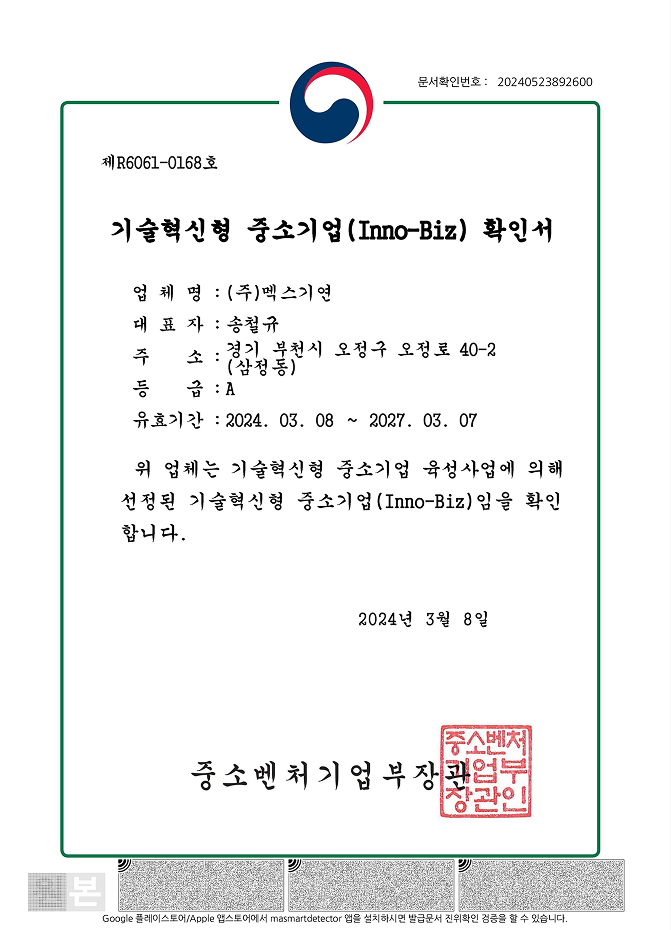

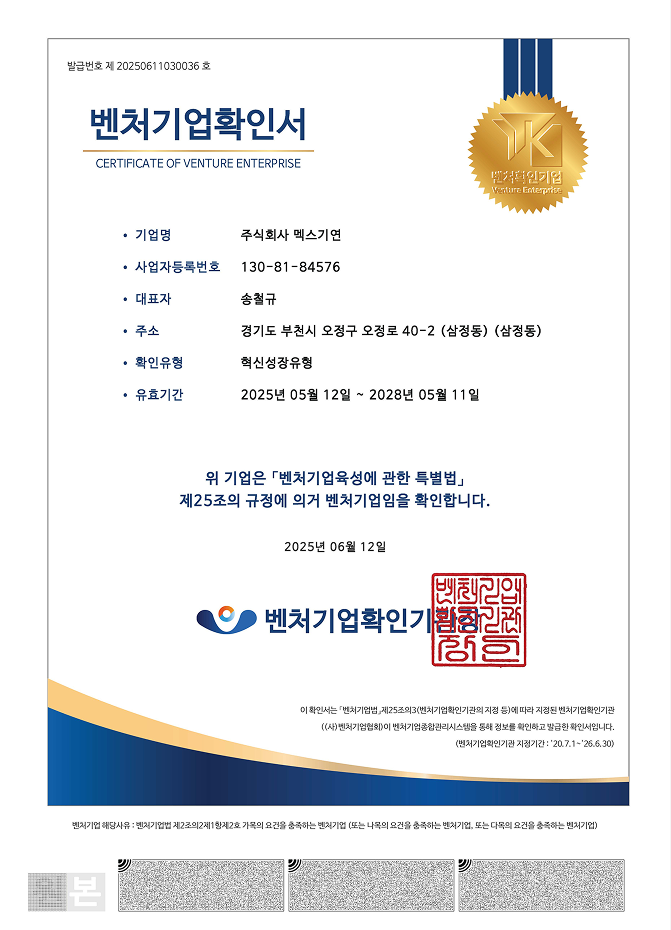

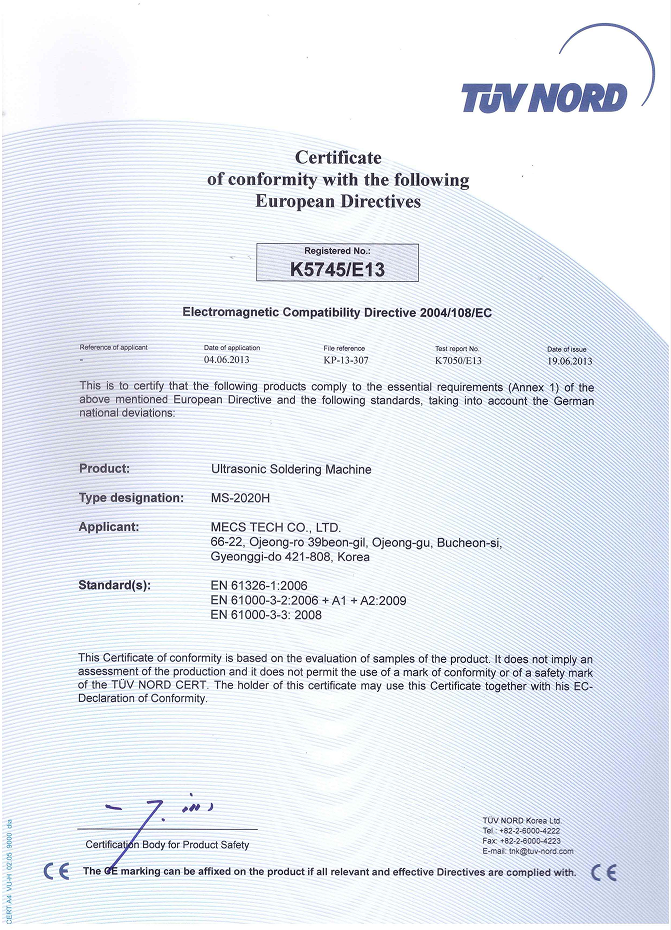

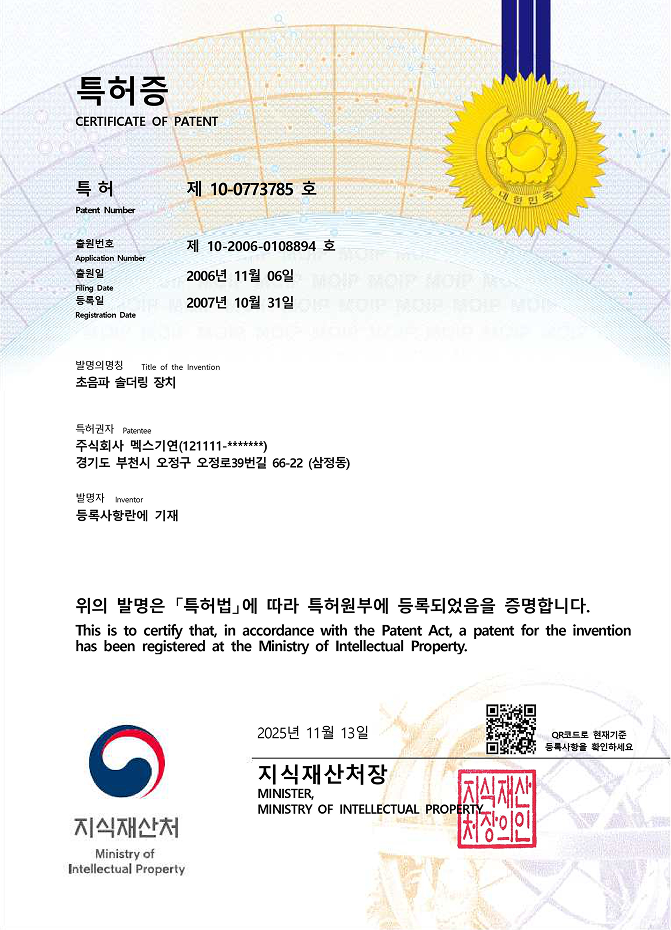

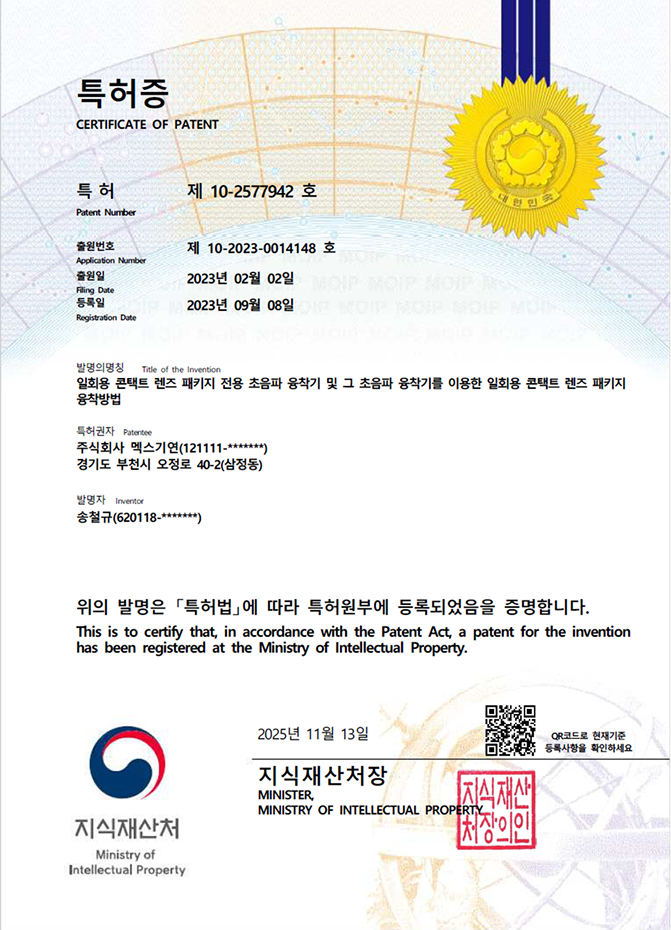

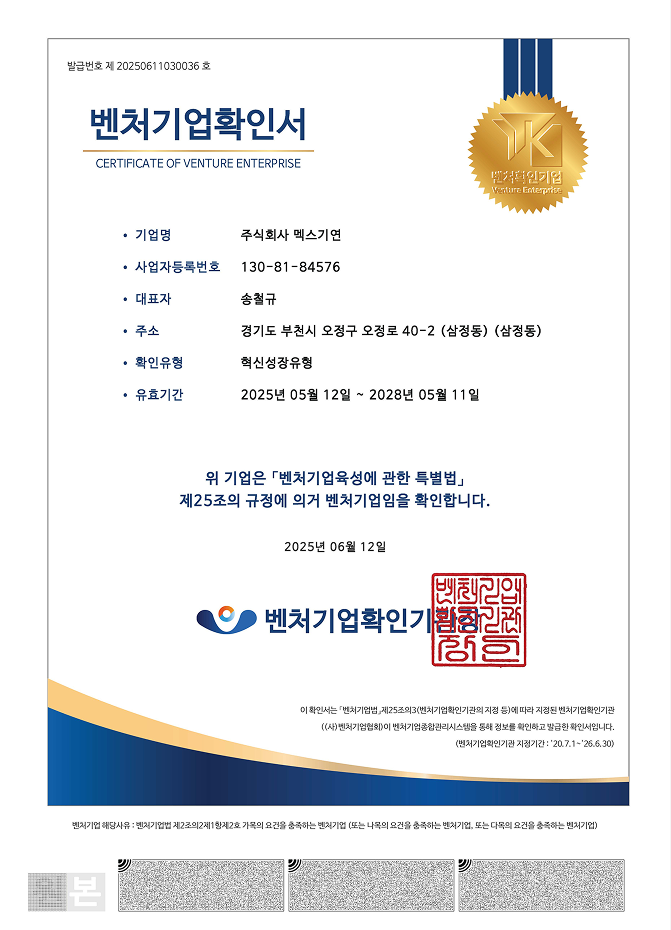

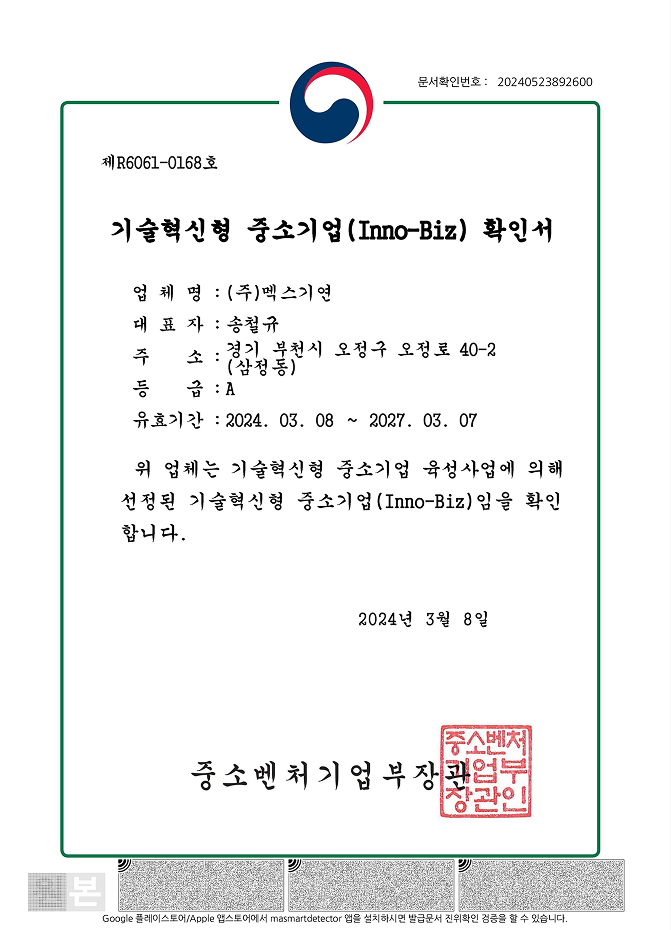

Certifications

Clients