- Applications

- Ultrasonic Plastic Welding

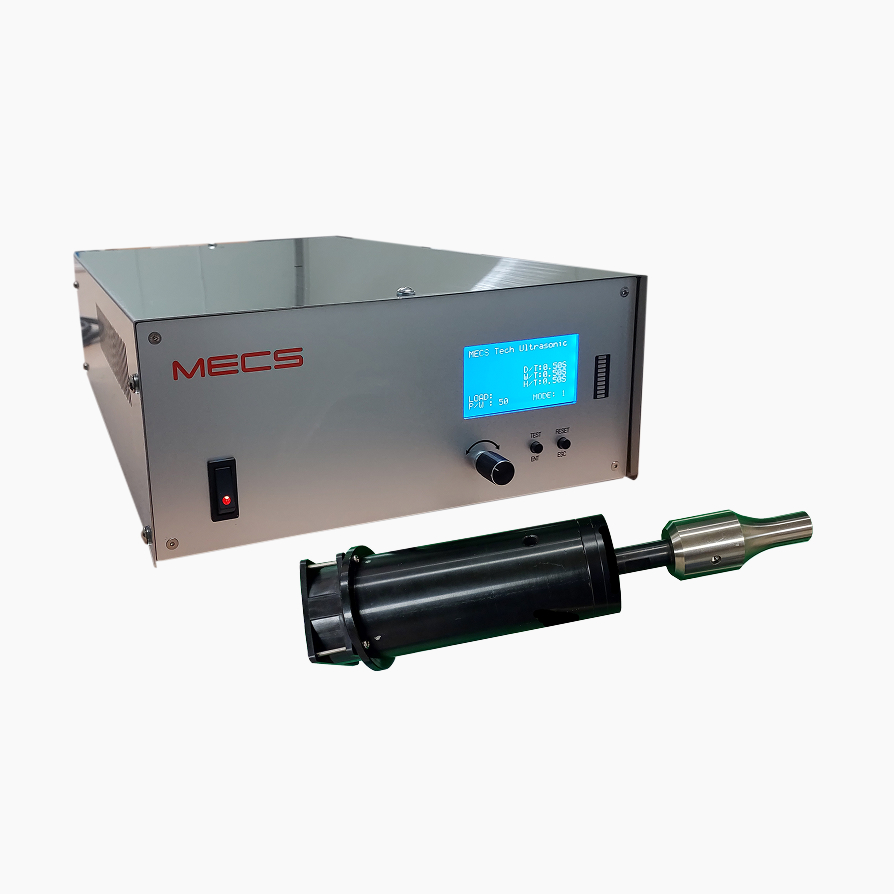

Ultrasonic Plastic Welding

Ultrasonic Plastic Welding

Ultrasonic plastic welding transfers high-frequency vibration energy to the joint interface of two plastic components, generating instantaneous frictional heat. This localized heat causes the contact surfaces to melt, and as the ultrasonic vibration stops, the materials cool and solidify, forming a molecular-level bond between the parts. Because this process requires no adhesives, screws, or external heat sources, it enables fast, strong, and precise welding, making it a highly efficient and reliable joining technology.

Ultrasonic plastic welding is widely used in joining and sealing processes for molded plastic components across industries such as automotive, electronics and electrical equipment, medical devices, home appliances, packaging, and consumer products. It is particularly suitable for production lines where appearance quality and leak prevention are critical, and it delivers high stability in automated manufacturing environments.

Application Examples

Medical industry

Cell culture devices, IV hose connectors, contact lens packaging cases

Batteries & electronics

Battery cases, mobile phone chargers, smartphone housings, vacuum cleaner handles

Automotive industry

Ultrasonic parking sensors, door trims, sound insulation components, wheel house interior and exterior parts

Home appliances & consumer goods

Washing machine drain pumps, refrigerator doors, air conditioner cross-flow fans, cosmetic containers

Water purification & filtration

Water purifier filters, various filter housings

Other industrial components

Lighters, plastic cases, and a wide range of injection-molded plastic parts