Ultrasonic Soldering

Ultrasonic Soldering

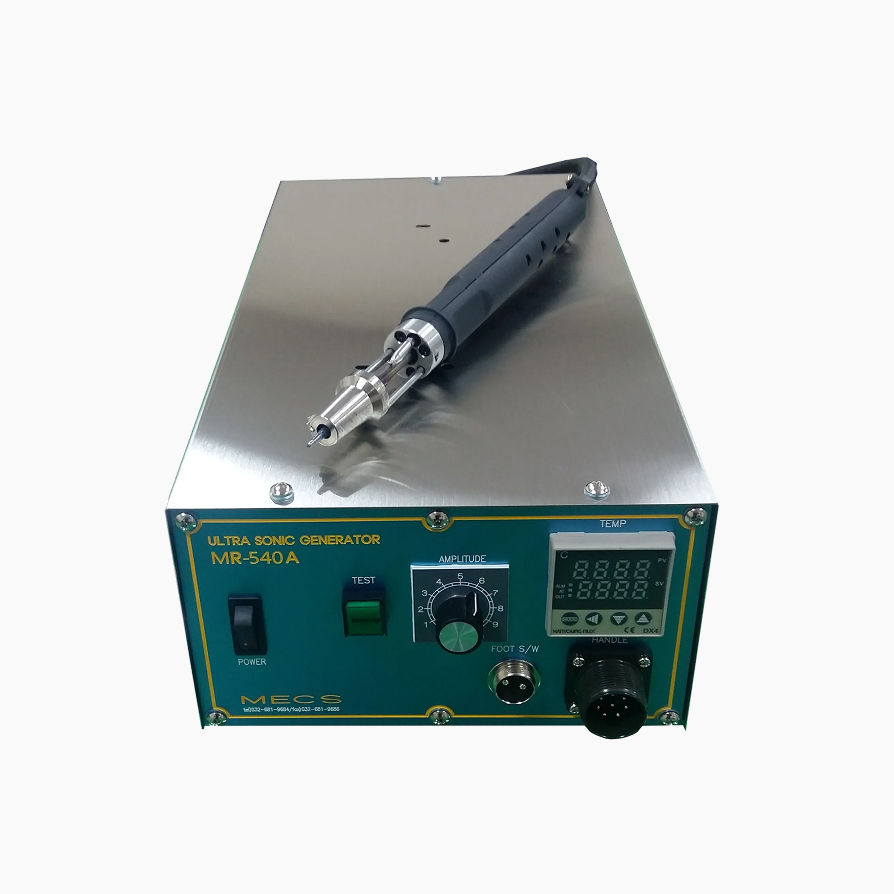

Ultrasonic soldering is an environmentally friendly joining technology that enables direct metal bonding without the use of flux by removing surface oxides through ultrasonic vibration. It is a method in which high-frequency mechanical vibrations in the ultrasonic frequency range generate cavitation in the molten solder, removing oxide layers from the metal surface and thereby enabling soldering. As a result, clean joints are formed without flux residue, enabling stable and reliable ultrasonic soldering between dissimilar metals such as aluminum and copper, with excellent electrical and mechanical performance.

Ultrasonic soldering is widely applied to metal wire, terminal, and PCB joining processes across industries including electronics and electrical equipment, motors, home appliances, automotive, and industrial power systems. It is particularly suitable for eco-friendly manufacturing where flux usage is restricted, high-reliability electronic modules, and components requiring high heat resistance and electrical conductivity. Compared to conventional thermal soldering, the process operates at lower temperatures and shorter cycle times, minimizing component damage and preventing galvanic corrosion while improving electrical reliability.

Application Examples

Home appliance & motor industry

Cooling fan motors (microwave ovens), BLDC motors (dishwashers, air conditioners, washing machines, large HVAC systems), Drain pump motors (washing machines), Reactors (air conditioners, washing machines, refrigerators)

Automotive industry

Clutch coils (automotive air conditioner compressors): Aluminum wire & copper terminals

Electronics & power supply industry

Transformers (forklift battery chargers), Capacitors, Inductors / chokes (UPS systems), Solenoid coils (inductors), Coil inductors

Display, optics & medical precision

External Electrode Fluorescent Lamps (EEFL for LCD TV backlight units), Superconducting wires for MRI equipment

Ultrasonic soldering iron applications

Sealing of laser amplifiers for communication equipment, Formation of tin busbars for solar cell modules