When You Lead, We Support

Products

- Products

- Ultrasonic Soldering

- Ultrasonic Soldering Machine

HOME

Products

Ultrasonic Soldering

Ultrasonic Soldering Machine

Product Overview

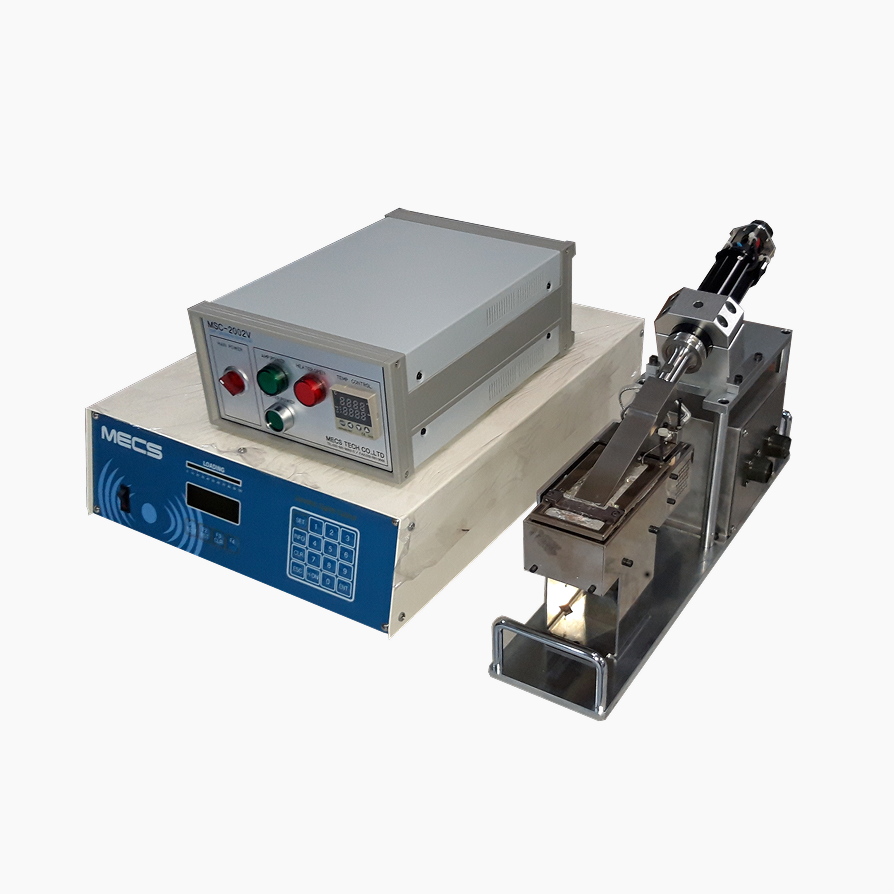

Ultrasonic Soldering Machine

No Flux · Eco-Friendly · Significant Cost Reduction

MECSTECH’s ultrasonic soldering system is an environmentally friendly, no-flux soldering solution that fundamentally overcomes the limitations of conventional flux-based soldering using harmful chemicals.

Ultrasonic vibration removes oxide layers on the soldering surface, allowing solder to spread uniformly and enabling stable bonding even on materials that are difficult to solder using conventional methods, such as glass, ceramics, and aluminum.

The system is available in horizontal, vertical, and immersion-type configurations depending on the soldering process, covering a wide range of applications from small-scale precision work to fully automated mass production.

Key Features

01

Eco-friendly soldering without the use of flux or chemical agents

02

Clean working environment with no hazardous gas emissions or wastewater

03

Strong, reliable joints with no corrosion, voids, or defects caused by flux residue

04

Ultrasonic vibration allows solder to penetrate uniformly into micro-gaps

05

Enables replacement of copper wire with aluminum wire (up to 80% cost reduction)

06

Improved productivity by eliminating flux application and cleaning processes

07

Applicable to difficult-to-bond materials such as glass, ceramics, and aluminum

08

Supports soldering of dissimilar materials (Al–Cu, Cu–glass, Al–ceramic, etc.)

09

Digital amplifier control with automatic frequency tuning (20kHz ±1kHz)

10

Adjustable ultrasonic amplitude: 10–100%

11

Soldering condition memory (preheating time, soldering time, ultrasonic intensity), up to 10 programs

12

RS-232C / RS-485 ultrasonic data communication support (optional)

Model Comparison

Model Type

Feature

Typical Applications / Main Uses

Horizontal-Type

- Ultrasonic soldering machine in which the ultrasonic

vibration is generated in the horizontal direction

- The most widely used ultrasonic soldering model

vibration is generated in the horizontal direction

- The most widely used ultrasonic soldering model

Precision soldering of electronic components such as lead

wires, electrodes, and terminals

wires, electrodes, and terminals

Vertical-Type

- Ultrasonic soldering machine in which the ultrasonic

vibration is generated from bottom to top

- It is applied to products that are difficult to solder using

a horizontal-type ultrasonic soldering machine

vibration is generated from bottom to top

- It is applied to products that are difficult to solder using

a horizontal-type ultrasonic soldering machine

Sensors, electrodes, glass-to-metal sealing,

coating and encapsulation processes

coating and encapsulation processes

Immersion-Type

- Ultrasonic soldering machine designed for easy tool

horn replacement

- Suitable for manual soldering of relatively small electronic

components or thin wires

horn replacement

- Suitable for manual soldering of relatively small electronic

components or thin wires

Mass production and automated soldering lines

requiring uniform quality

requiring uniform quality

Specifications

Model No.

MS-2020H

MS-2020V

MS-1030H

Frequency

20 kHz ± 1 kHz

20 kHz ± 1 kHz

30 kHz ± 1 kHz

Max Output

2,000 W

1,000 W

Temperature Range

150~400°C

Line voltage

AC220V (Single phase) / 60 Hz

Ultrasonic Generator

Size

Weight

434(W) × 600(L) × 140(H) mm

20 kg

Ultrasonic Soldering Machine

Size

Weight

264(W) × 531(L) × 220(H) mm

235(W) × 235(L) × 490(H) mm

130(W) × 540(L) × 290(H) mm

30 kg

5 kg

Temperature Controller

Size

Weight

250(W) × 320(L) × 140(H) mm

Built-in Type

5 kg

-